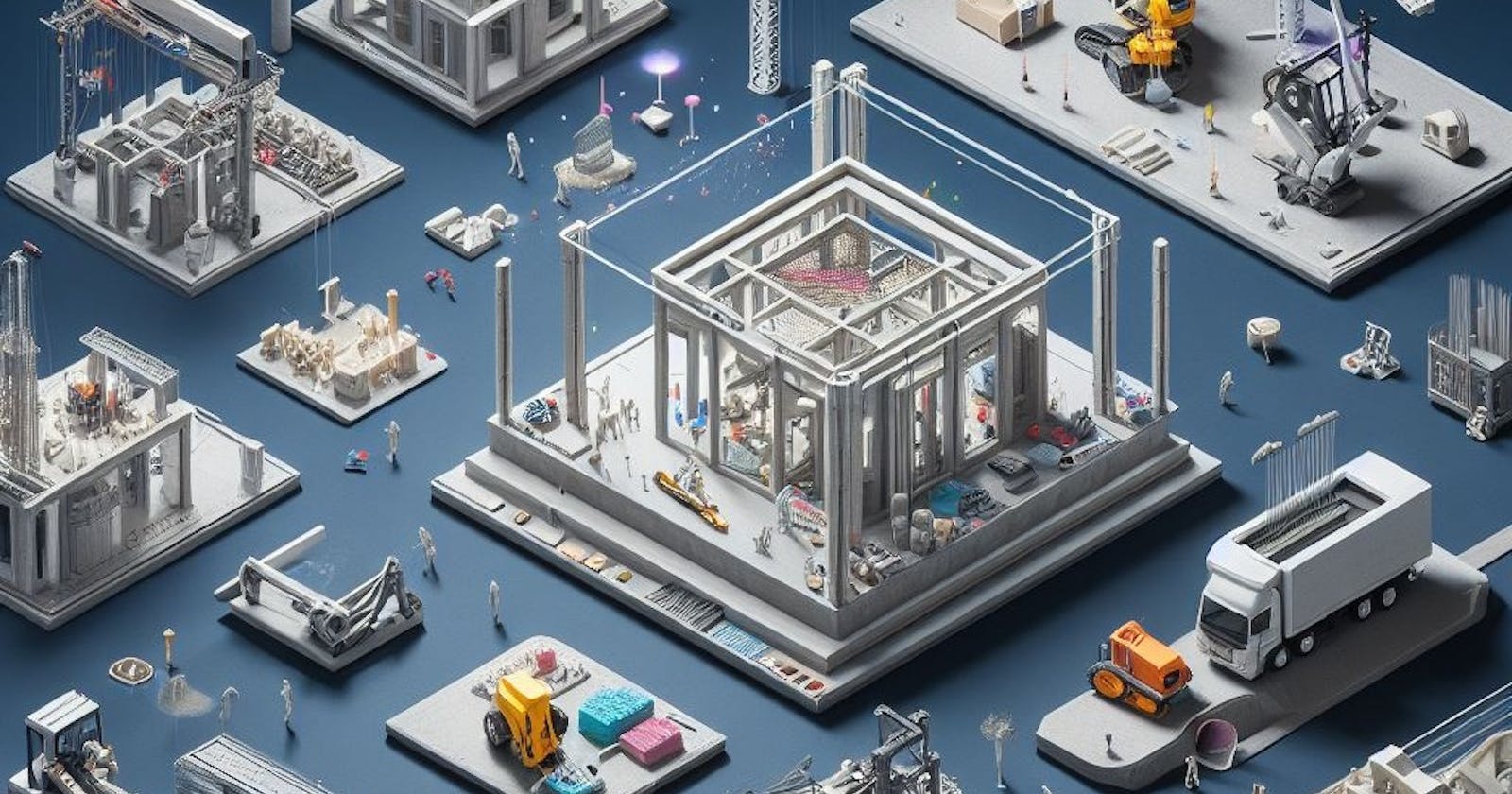

Envision a transformation in the construction world, where the traditional sounds of hammering and chiseling are replaced by the subtle buzz of 3D printers. At the forefront of this revolution is 3D concrete printing, a groundbreaking technology set to reshape the very foundations of construction. This innovation brings forth a multitude of benefits, including increased speed, cost savings, and most notably, a boost in sustainability.

3D concrete printing stands out as a cutting-edge technology in the building sector, utilizing immense 3D printers that can reach up to 30 feet in both height and width. These printers use a nozzle to dispense a substance akin to concrete, operating through either gantry or robotic arm mechanisms, and meticulously layering material to construct your envisioned structure[1].

However, the capabilities of 3D printing in construction extend far beyond just concrete. The technology accommodates a diverse array of materials, including mortar, plastic, and even recycled debris. Picture this: buildings emerging from the remnants of old structures, or being crafted from local natural resources, or even from lunar and Martian soil. 3D concrete printing is not just an economical alternative; it’s a step towards a more sustainable future, a vital consideration for developing countries.

The Dawn of 3D Concrete Printing: Beyond a Giant Printer

Revolutionizing Construction with 3D Printers

The construction industry is witnessing a profound change with 3D concrete printing at its core, employing gigantic printers that can span up to 30 feet in height and width to dispense a concrete-like material through a specialized nozzle. These massive printers come in two main varieties: gantry systems and robotic arms, working tirelessly to place layer upon layer of material, bringing architectural visions to life[2].

Exploring a Variety of Materials

Interestingly, the term “3D concrete printing” doesn’t fully capture the technology’s range, as it works with materials beyond just concrete. It embraces a variety of substances such as mortar, plastics, and even recycled materials. The technology also explores the use of local resources like lunar soil, Martian dust, and more, enhancing its versatility and paving the way for sustainable construction practices, albeit still in the research phase. [2]

Leading the Way: Innovators and Pioneers

Various companies have eagerly entered this emerging field, with notable names like CyBe, known for their “CyBe Mortar”, and WinSun with their innovative “Crazy Magic Stone” made from a unique cement blend. The economic advantages of 3D printing in construction are clear, with reductions in material costs and faster project completion times.

Benefits and Challenges

The advantages of 3D concrete printing extend beyond just economics. The unique characteristics of 3D printed structures offer enhanced thermal regulation, providing increased resilience to extreme weather events like hurricanes. However, it’s crucial to acknowledge the challenges, including high initial investment and the need for regulatory approval.

Looking Ahead

As 2023 progresses, the planning of entire neighborhoods and multi-house developments using 3D concrete printing signals the technology’s growing maturity and potential to outperform traditional construction methods in both cost and speed.

Potential and Challenges of 3D Concrete Printing

Material Innovation in 3D Printing

3D concrete printing stands out for its flexibility in material selection. Despite its name, the technology is not confined to just concrete; it extends to a variety of mixtures including modified mort ars, plastic blends, and sustainable options like recycled plastics and local raw materials[1].

Driving Sustainability Forward

The incorporation of local and recycled materials is a strategic move towards a more sustainable building practice, reducing transportation costs and the overall carbon footprint. It also brings down construction expenses while promoting eco-friendly building methods.

Proprietary Materials: Innovation and Challenges

Several companies are developing proprietary materials tailored to their printing technologies, providing a competitive edge. However, this could also pose challenges for widespread adoption due to potential compatibility issues, leading to vendor lock-in situations.

Economic Aspects

Cost-Effectiveness: A Balanced View

While 3D concrete printing is celebrated for its potential cost savings, it hasn’t definitively outperformed traditional construction methods in this regard. The overall cost savings are yet to be realized, particularly when considering the initial investment required for 3D printing technology.

Speed: A Key Advantage

One of the standout features of 3D concrete printing is its unparalleled construction speed, allowing for the rapid creation of building segments, translating to significant labor cost savings[1].

The Future Landscape

The technology’s potential is highlighted by the current planning of multi-house developments and entire neighborhoods utilizing 3D concrete printing, indicating its capability to surpass traditional building methods in terms of both cost and speed.

Resilience in Extreme Weather

3D printed concrete structures also demonstrate exceptional resilience, maintaining internal temperature stability and withstanding extreme weather events like hurricanes, adding another dimension to their appeal.

Challenges and Future Questions

Despite the promise, several questions remain, such as the potential issues arising from proprietary printing materials and how sustainable building practices can be integrated into this rapidly evolving technology. Time and further research will provide the answers.

Efficiency and Sustainability of 3D Concrete Printing

Maximizing Material Usage

The rising field of 3D concrete printing is not just about faster building methods; its sustainability aspects are equally noteworthy. The technology embraces a wide range of materials including various types of mortar, plastic, and recycled substances, as well as natural materials like lunar soil and Martian dust. This diversity in material choice enables a more sustainable approach to construction, utilizing local and waste materials for ecological benefits.

Scale and Speed: Economies in Action

Although initial investments in 3D printing for construction have not shown significant cost reductions compared to traditional methods, the balance is shifting. Builders are experiencing reduced material costs and a faster construction timeline, indicating that larger scale projects could potentially outperform traditional methods in both cost and speed.

Energy Efficiency in Construction

3D-printed concrete structures also excel in energy efficiency, maintaining thermal stability and demonstrating resilience against extreme weather conditions, offering sustainability advantages over traditional wood or brick structures[1].

The Labor Equation

While material and time savings are evident, the impact on labor cannot be ignored. The technology reduces labor costs, but it also raises ethical questions related to job displacement, necessitating a broader conversation on this issue.

Unleashing Architectural Creativity

One of the less tangible but profoundly impactful benefits of 3D concrete printing is the freedom it offers architects, enabling intricate designs and structures that would be impractical or prohibitively expensive using traditional methods.

Conclusion

3D concrete printing is a technology in its infancy, yet it is rapidly evolving and holds great promise. While its economic potential is yet to be fully realized, the advantages it offers in terms of sustainability, speed, and labor efficiency are undeniable. As larger projects become more common, we may witness a paradigm shift in construction, redefining sustainable building practices.

Further Reads

If you're eager to explore more about the fascinating world of 3D concrete printing, there are plenty of resources to satisfy your curiosity. Dive into the realm of the best concrete printers, each offering unique capabilities and innovations in this cutting-edge field. Uncover the numerous advantages of 3D concrete homes, and learn how this transformative technology is reshaping the housing industry. Investigate the strength and resilience of this material with how strong is 3D concrete, and delve into the future possibilities of this technology in 3D concrete printing: is it the future?.

For practical insights, discover how long it takes to 3D print a house and explore the technical aspects of the printing process with admixtures for 3D concrete, shedding light on the various compounds that enhance the printing experience. Learn about the curing time of 3D concrete, a crucial aspect for ensuring structural stability. Finally, gain a thorough understanding of the entire process with how 3D concrete works, providing a step-by-step guide through this innovative technology. These articles together offer a comprehensive knowledge base for anyone looking to delve deeper into the world of 3D concrete printing.

References

All3DP Pro: "3D Concrete Printing – The Ultimate Guide" by Ile Kauppila, Updated Aug 16, 2023. URL: https://all3dp.com/1/3d-concrete-printing-guide/

Automation and the Value of Work - Ricky et al. https://openresearch.ocadu.ca/id/eprint/3889/